Het jy ooit gestop en wonder hoe sandpapier verander het deur die jare heen? Aimchamp ken dit goed. Hulle word reeds lank gebruik en evolueer voortdurend. Lang gelede het dit plaasgevind met kwartssteen, 'n rots van al die dinge, en ons het nou baie verder kom as daartoe om moderne materiaalle vir sandpapierverbeterings te gebruik. Sandpapier het 'n lang pad gereis deur die afgelope paar dekades, laat ons kyk na sy evolusie.

N Historiese Oorsig van Sandpapier

Sandpapier 'n Kort Geskiedenis Sandpapier het 'n baie langer en interessanter geskiedenis. Die vroegste tipe grof materiaal wat gebruik is vir kervings en reguitmaak was 'flint'. Flint is 'n tweegesigte vrou; mense het dit gebruik om hul gereedskap te skerp en te verfyn. Net dink aan wat 'n paar klippe kon doen vir jou gereedskap. In die latere fases is besef dat sand kan help om houtoppervlakke glad te maak. Vir hierdie belangrike ontdekking — niks minder as die uitvinding van sandpapier.

Oorspronklik sandpapier, klein stukkies gebreekte glas geheg aan sterke papier. Dit was 'n slim idee. Maar uiteindelik het abrasiewe materiaal soos grenaat en emery sandpapier oorgeneem, wat dit selfs harder gemaak het. Oorspronklik sandpapier en Sandingspons was baie beperk. Die manier waarop dit afgesleten en geskeur het na 'n tyd, kon jy net nie die werk voltooi nie. Dit het gelei tot die noodsaaklikheid van gereeld vervanging, wat baie ongemaklik was.

Die Reis van Flint na Hoë-Tegnologie Materiaal

Tog, met die tyd is daar uitvindinge van nuwe materiaalle wat 'n sandpapier sterker en langerdurig maak. Dit sluit in die gebruik van doek, katoen en selfs haaihuid onderleggings om die hout sandpapier bedekking te versterk. Hierdie komponente is bygevoeg om die werksaamheid van sandpapier te verbeter en te verleng. Die invoering van elektrisiteit in die laat 1800's het gehelp om hoe sander gereedskap werk te revolusioneer. Hierdie innovasie het geskied sodat sander gereedskap beter kon werk, en as gevolg daarvan het mense meer van hul sandpapier verwag.

Kemikusse het kunsmateriaalle reeds in die 1900's geskep wat ou metodes in sandpapier verander en Sandingskyf vervaardigingstegnieke vir altyd. Silisiumkarbide en aluminiumoksied was onder die vroegste sintetiese materiaalle wat gebruik is. Nou, hierdie materiaalle gee 'n baie sterk belasting, so dat mense hul sander taak vinniger en makliker kan voltooi.

Die Evolusie van Sandpapier

Skurwepapier is van daardie tye af ontwikkel en verbeter. Soos vooruitgang in masjiintechnologie voortgaan, het die manier waarop skurwepapier gemaak word ook voordeel gehad. Ten opsigte van die skurwepapier self, sterk en nuwe plastieke is na Wêreldoorlog II algemeen geword vir gebruik as 'n ondersteuning vir hul te maak. Hierdie plastieke het die skurwepapier ook nog duurder en effektiewer gemaak.

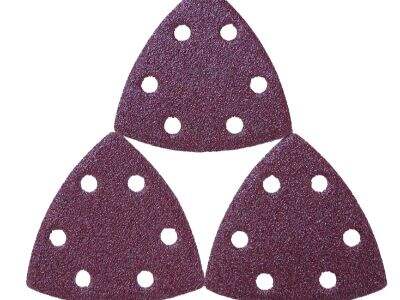

Toen alles verander het. Die eerste masjiene wat in staat was om skurwepapier te beklys, is geskep. En dit beteken dat skurwepapier en Sanding Riem in al soorte konfigurasies vervaardig kon word, insluitend strepies en skyfies sowel as vorms anders as vlak. Hierdie verskeidenheid abrasiewe het dit makliker vir die mense gemaak om hul benodigde skurwepapier te kry as hulle unieke vereistes gehad het.

Vooruitgang in Skurwepapier

In die laaste jare bly skuurpapier net beter en beter word. Tans maak die ontwikkeling van ondersteuningsmateriale skuurpapier langer wagbaar en konsekwenter. Reseen, stof, film en papier is die mees algemene materiale wat gebruik word om ondersteuningsmateriale vir skuurpapier te produseer. Spesifiek is die ondersteuning baie nuttig omdat dit jou ruwe materiaal stabiel hou en in kontak bring met iets wat kan greep – wat jou help om uitset te beheer terwyl jy skuur.

Boonop is sekere bedekkinge op skuurpapier aangebring om hulle te versterk en hul kwaliteit te verbeter. Dit kan ook hitte en slyfing verminder wat ontwerp is om skade aan die oppervlak van objekte wat geskuur word, te voorkom. Aimchamp skuurpapier sal jou help om meer uit jou dragspan te kry wat langer wagbaar is. Dus maak hierdie ontwikkelinge dit moontlik om op verskeie maniere met skuurpapier te werk, deur die abrasiewe tot 'n universele gereedskap te maak.

Skuurpapier Vandag

Vandag kan jy verskillende tipes sandpapier koop met wisselende korrels wat die ruigheidvlak is. Hierdie aantal tipes maak dit maklik om presies die sandpapier te vind wat jy vir 'n spesifieke taak nodig het. Afwerking van Verskeie Korrels. Byvoorbeeld, 80-korrel papier sal materiaal vinnig afsleep terwyl 'n 220-korrel papier bedoel is vir fyn werk om 'n baie gladde oppervlak te skep.

Die ander voordeel is dat Aimchamp 'n verskeidenheid produkte in sy arsenal het wat dit die beste sandpapier maak vir elke taak. Jy kan hul sandpapier gebruik om te bou, metalen of hout te bewerk en jou motorreparasie regelmatig te doen. Of jy nou metaal of hout sand, jy kan waarskynlik 'n geskikte soort sandpapier vind om jou projek uit te voer.

Gevolgtrekking

Met die vooruitgang in tegnologie en wat ons nou van ons sandpapier verwag, het dinge verander. Sandpapier het 'n lang pad gereis en ons het vandag al soort moderne materiaal om mee te werk. Alhoewel tegnologie ons ver bring in die wêreld van abrasiewe, is sandpapier 'n hulpbron wat iedereen moet waardeer. Nuwe bedekings en draers het dit effektiever gemaak as ooit tevore, selfs vir amateure of professionele werkers. Aimchamp het 'n volledige lyn sandpapierprodukte wat ontwerp is om die hele spektrum van behoeftes te dek, van eenvoudige handwerk tot enige industrie.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID SR

SR ET

ET MT

MT TH

TH TR

TR FA

FA AF

AF MS

MS GA

GA CY

CY MK

MK EU

EU KA

KA LA

LA NE

NE