إزالة الصدأ تكون مفيدة جدًا عند العمل مع المعدن. يأخذك حزام الرمل الجيد إلى مستوى ناعم ولامع وأحترافي في مشاريعك. لكن عليك أن تختار بين أنواع مختلفة من أحزمة الرمل، وهذا قد يكون أمرًا مخيفًا قليلاً. سيساعدك هذا الدليل على اتخاذ القرار الصحيح بشأن اختيار حزام رمل لصناعة المعادن. سنشارك أيضًا بعض النصائح المفيدة حول كيفية استخدامه بشكل صحيح وتحسين النتائج. إذن، ارتدِ نظارات السلامة ودعونا نتعلم عن أحزمة الرمل!

كل شيء يتعلق بحزام الرمل: اختر الحزام المناسب

اختيار حزام رمل لصناعة المعادن هو مهمة بالغة الأهمية. هناك بعض النصائح التي قد تساعدك للبقاء في الاتجاه الصحيح:

حجم الحبيبات: يشير حجم الحبيبات لشريط الرمل إلى مدى خشونته. لماذا تعتبر أرقام الحبيبات مهمة؟ إنها تؤثر في كيفية عمل الشريط. رقم حبيبات منخفض، مثل 60، يعني أن الشريط سيزيل كمية كبيرة من المادة بسرعة، ولكنه قد يترك خدوشًا أعمق على المعدن. أما رقم حبيبات أعلى، على سبيل المثال 220، فهذا يعني أن الشريط سيترك خدوشًا أخف، مما يمنحه مظهرًا أكثر نعومة وبريقًا. عند اختيار حجم الحبيبات، اأخذ بعين الاعتبار نوع الانتهاء الذي ترغب به لمشروعك.

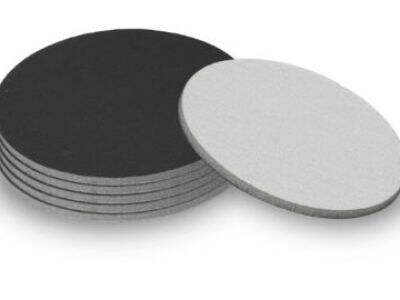

الدعم المادي: تلعب الأحزمة المنتجة من مختلف التركيبات المادية ومادة الدعم دورًا كبيرًا فيما يتعلق بكيفية تصرف الحزام. الورق، القماش، والبوليستر هي بعض المواد الداعمة الأكثر استخدامًا لهذا النوع من أحزمة الصنفرة. هذه أقل تكلفة مقارنة بالمنتجات ذات الدعم الورقي، لكنها أكثر عرضة للتلف عند إعادة الاستخدام بعد العديد من الدورات. الدعم القماشي أقوى، وهو خيار أفضل للأشخاص الذين يقومون بأعمال ثقيلة. أما دعم البوليستر فهو قوي ومرن للغاية، ولكن ذلك لا يعني أنه يناسب كل نوع من المعادن. اختر المادة التي ستناسب احتياجاتك بشكل أفضل.

نصائح نهائية: عندما تختار شريط صنفرة، تأكد من أنه يناسب الأحجام والأشكال للأدوات التي تمتلكها وللمشروع الذي تقوم به. هناك أنواع مختلفة من العرض والطول والأشكال لشريط الصنفرة. اختر الحجم والشكل المناسبين لتوفير البعد المناسب لمعداتك وخواص المهمة التي تقوم بها. هذا سيمنحك القدرة على العودة إلى مهام العمل بطاقة كبيرة، مع تحقيق نتائج فعالة.

هناك العديد من الخصائص الأخرى التي قد ترغب في معرفتها عند اختيار شريط صنفرة مناسب. هذه تشمل حجم الجسيمات ومواد الدعم:

نوع المادة الخشنة: هناك عدة أنواع من المواد الخشنة التي يمكن استخدامها في تصنيع أحزمة الرمل. تشمل هذه الألمنيوم أكسيد، زركونيا ألومينا، السيراميك ألومينا، أو كربيد السيليكون. كل منها لديه خصائصه الخاصة التي تحدد أداء حزام الرمل. ربما تعمل بعض المواد الخشنة بشكل أفضل على معادن معينة أو أنواع مشاريع معينة وبحث بسيط قد يساعد في تحديد أي منها يناسب احتياجاتك بشكل أفضل.

وصلات الحزام — نوع الوصلة المستخدمة لربط حزام الرمل المطاطي — يمكن صنع وصلات الحزام بعدة طرق؛ على سبيل المثال، وصلة طرفية، وصلة تداخلية أو وصلة شريط. يمكن أن يؤثر نوع الوصلة (الاتصال) على مدى قدرة الحزام على البقاء معًا أثناء الاستخدام. يعتبر وجود وصلة قوية أمرًا لا غنى عنه لضمان عدم انكسار الحزام أثناء الاستخدام، مما قد يتسبب في الحوادث أو العيوب في مهمتك.

تقييم السرعة: معظم أوراق الصنفرة تحتوي على تقييم للسرعة يخبرك بالسرعة القصوى الآمنة لاستخدام حزام الصنفرة. هذا تفصيل مهم، لأن استخدام سرعة أعلى من الموصى بها قد يؤدي إلى انكسار الحزام. ليس فقط يمكن أن يفسد مشروعك، ولكنه قد يكون خطيراً أيضًا. للسلامة، تأكد دائمًا من التحقق من تقييم السرعة قبل استخدام حزام الصنفرة في عملك.

نصائح لاستخدام أحزمة الصنفرة

بعد اختيار حزام الصنفرة المناسب لتطبيقك المحدد، فإن الاستخدام الصحيح سيكون الفرق بين النتائج المرغوبة وغير المرغوبة. إليك بعض الأمور التي يجب مراعاتها:

استخدام معدات السلامة المناسبة: ارتدِ دائمًا المعدات الأمنية الصحيحة مثل النظارات الواقية لحماية عينيك، وواقي الأذن لحماية أذنيك من الأدوات أو الضوضاء العالية، وكمامة الغبار لمنع استنشاق الجزيئات الضارة. ضع السلامة دائمًا في المقام الأول!

قبل تركيب حزام الصنفرة، يجب عليك إطفاء مصدر الطاقة للمعدات التي تم تركيبها منذ فترة، مما يضمن عدم حدوث أي عمل غير آمن في منشأتك.

عند استخدام الحزام الخاص بك، يجب ألا يكون قد تعرض للتلف، وعلى أي حال قبل إجراء الاتصال، تحقق من استبداله إذا كان معطوبًا حقًا قبل وضع التروس. لكن قد يظهر مشكلة بسبب الاستخدام الخاطئ أو قد يؤدي إلى نتائج غير فعالة، وفي أسوأ الحالات قد يكون كارثيًا.

استخدم ضغطًا خفيفًا وحافظ على وتيرة ثابتة أثناء الرمل. استخدام ضغط مفرط قد يتسبب في قطع جزيئات الطحن بعمق أكبر وتآكلها بشكل أسرع مع مرور الوقت. الضغط الأقل سيساعدك في الحصول على إنهاء أكثر نعومة.

تأكد من أن سطح المعدن نظيف وخالي من الشوائب. القيام بذلك سيمنع الجسيمات من انسداد حزام الرمل مما يمكن أن يقلل من فعالية أداة الرمل الخاصة بك.

اختيار أحزمة رمل عميقة للمهام الثقيلة

إذن، إذا لم تقم بتقسيم المشاريع الثقيلة المتعلقة بصناعة المعادن مثل طحن أو تشكيل قطع معادن ثقيلة، فإنك تحتاج أيضًا إلى أحزمة رملية ذات جودة عالية. هذه هي بعض المتطلبات البحث عن حزام عندما نتحدث عن هذه الأعمال، والتي تساعد الأشخاص الذين يعملون في بيئات شديدة. على المدى الطويل، الاستثمار في أداة أكثر قوة مع تحكم في سرعة متغير، مدمجة مع ورق جودة جيدة، يمكن أن يتيح لك الرمل بطريقة ناعمة وكفؤة لأكثر المهام تحديًا.

إنهاء مشاريع المعادن

الآن بعد أن قمت بتصقيل المعادن إلى درجة النعومة التي تحتاجها، حان الوقت لإضافة اللمسات النهائية. هذه هي المرحلة التي يمكن فيها لجماليات مشروعك أن تظهر بأفضل حالاتها. إليك بعض التقنيات الشائعة في الانتهاء من العمل:

يمكنك تصقيل المعدن بشكل أكبر للحصول على لمعان جيد باستخدام عجلة التصقيل أو مرفق الفرشاة الخاص بالأداة. وهذا سيضيف لمسة احترافية للغاية لمشروعك النهائي.

حتى طبقة الوضوح أو الشمع الذي يمكن تطبيقه على المعدن يضمن الحماية من الصدأ والتآكل، مما يمكن أن يضمن في النهاية استدامة جاذبيته على مر السنين.

يمكنك استخدام حل الباتينا لإضافة مظهر قديم أو متضرر لمشروعك. مثل هذا التأثير يمكن أن يمنح مشروعك شخصية وشخصية فريدة.

باستخدام أحزمة الرمل المناسبة ستتمكن من تنفيذ أعمال معالجة المعادن الخاصة بك بنتائج رائعة إذا اتبعت هذه الحيل والتقنيات. وأخيرًا وليس آخرًا، تذكر دائمًا أن السلامة هي الأولوية رقم واحد واختر أفضل حزام رمل بناءً على احتياجاتك. ستتمكن من إتقان معالجة المعادن ومع التدريب المنتظم والأدوات المناسبة في يديك؛ ستصبح محترفًا في هذا الحرف. سعيدًا بالرمل!

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID SR

SR ET

ET MT

MT TH

TH TR

TR FA

FA AF

AF MS

MS GA

GA CY

CY MK

MK EU

EU KA

KA LA

LA NE

NE