研磨は、製品を向上させるためにさまざまな工場や製造プロセスで広く使用されている重要な工程です。これは、素材の表面から目に見えないほどの小さな部分を取り除き、滑らかでよりきれいな仕上げを作ります。この作業には、サンドペーパー、研削盤、またはベルトなどの道具が使われます。これらの道具は、粗いエッジを整え、すべてを美しく仕上げます。私たちは一般的に研削について話すときに、荒削りと精密削りという2つの形態があります。

荒削り

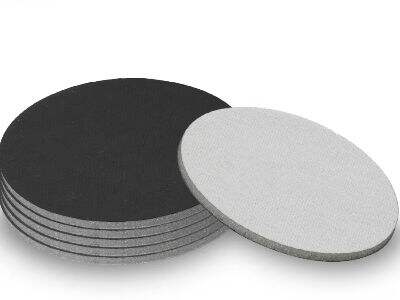

荒削りとは、大量の材料を迅速に除去するプロセスです。それは大きなツールを使って木を切るようなものです——早くその木材を取り除きたいのです。この種の研削は、鋳物や鍛造部品と呼ばれる大きな部品から余分な材料を除去するために使用されます。このプロセスでは、大口径で粗い研削盤や強力な研磨ベルトが使用され、研削プロセスを加速します。 スクーリングパッド 迅速に削除できますが、 souvent 表面を不均一で粗くし、その後追加の作業が必要になる場合があります。滑らかで美しい状態にするためです。

精密研削

しかし、精密研磨はまったく異なるタイプのプロセスです。非常に慎重であり、時間をかけて滑らかで正確なものを作り出します。これを美しいものを生み出すアーティストのように考えてください。すべての詳細が重要です。部品が完全に密着する必要がある場合、例えば飛行機や医療機器、または他のハイテク装備の場合、精密研磨が使用されます。それは 砂帯 微細な研磨輪を使用し、一度にわずかな量の材料を削除することで、非常にタイトな表面を残します。すべては精密さについてです!

荒削りと精密研磨の違い

荒削り対精密研磨:知っておくべき違い 砂利スポンジ 非常に効果的で、私たちが荒研ぎを行う場合、それは速くて効果的な方法であり、大きな面の成形に役立ちます。不要な材料を迅速に除去したり、欠陥を修正したりできます。しかし、デメリットは、これが有时候には「粗い」仕上げになることです。これは、表面が美しく見えず、後で美しく見せるために追加の作業が必要になる可能性があることを意味します。一方、精密研削は遅いプロセスですが、非常に制御されています。しかし、専用の設備と訓練を受けた労働力を必要としますが、追加の手順なしでインジェクション時に美しい滑らかな仕上げを与えてくれます。

精密研削の利点は何ですか?

では、なぜ精密研磨を選ぶのでしょうか?それは、望む通りの正確な寸法と形状を形成する可能性があるため重要です。この技術はあらゆる種類の材料に適用できます:プラスチック、金属、セラミックスなどその他も然りです。精密研磨はまた、部品が完全に適合することにより、部品の耐久性を向上させることも可能です。同一に作られたものは簡単に曲がったり、折れたり、摩耗したりしません。一方で、荒い研磨は熱がたまり、加工中の物を損傷や変形させる問題を引き起こすことがあります。

私たちのトレーニングプログラムは2023年10月まで実施されます。私たちは専門家であり、合計して数十年の経験を持っていますので、最高の精度で製品を製造するために最良のツールや技術を提供することができます。私たちに製造を任せれば、すべてが順調に進むようお手伝いします!私たちがどのようにお手伝いできるか詳しく知りたい場合は、ぜひご連絡ください。すぐにご返信いたします!

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID SR

SR ET

ET MT

MT TH

TH TR

TR FA

FA AF

AF MS

MS GA

GA CY

CY MK

MK EU

EU KA

KA LA

LA NE

NE