The wood-working is an interesting act of creating something with the help of woods. It is amazing and gives you a ton of freedom. Woodworking is something that anyone can do, young kids and adults alike learn to master it. But at the same time, working with wood is also hard and can be very time demanding. The most challenging chore is sanding the wood smooth for final finishing. Enter in サンディングベルト by Aimchamp, the essential tool that makes woodworking less of a pain and more profitable. A sanding belt lets you have a fine finish on your projects.

What Are Sanding Belts?

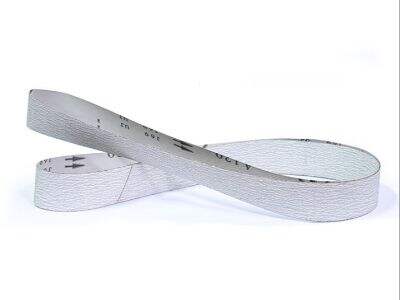

Sanding belts — these are special devices for grinding wood so that its surface is flat. They are a solid, almost sandpaper like material, and they go on this contraption called a belt sander. The working of this machine is very nice as it moves the sanding belt at high movers. This fast, efficient process of the サンディングベルト enables it to smooth out wood quickly and keep this a little bit lighter on your project.

You get better finish for your woodworking project when you use a sanding belt. The belt sander with a sanding belt is used to smooth the wood surface and remove any small splinters or rough edges. This way when you finally sand it, it is very smooth and perfect when you are going to paint something or leave the wood in its natural state.

How Sanding Belts Are Made?

A sanding belt consists of three distinct layers. First is the section that grinds away at wood called the diamond grit. The second layer is a unique adhesive agent that keeps the coarse material stuck to your feet. The bottom layer — typically composed of heavy, durable material such as cloth or rubber so it can provide support for the サンディングベルト and help a belt last.

The raw materials used in sanding belts come from a variety of types. This includes popular types such as aluminum oxide, silicon carbide, or zirconia alumina. Each of these materials have their own unique characteristics that make them great for different woodworking needs. They will be the best to decide and choosing can fetch you more better results than effort.

Sanding Belts: Where Does It Get Worked On?

You can use Sanding Belts for any type of woodworking projects. It is often used in the industry of furniture manufacturing. When using, it is critical to place them on furniture chairs, tables and cabinets in order to achieve a perfect finish. So if you have some sanding belts and are worried about them lying worthless at the corner, then DIY with sanding belt is not a bad option. For instance, when you are constructing shelves or a picture frame perhaps even bird houses.

You can use the sanding belts even for hardwood types of wood as well. These are made from hardwood like oak, which is very strong; or softwood as in pine that's lighter and easy to work. Do note that sanding belts are also able to be used on its composite materials MDF (Medium-Density Fiberboard), and plywood. Therefore a sanding belt is the best way to get that final fine technicality on any wood you are working with.

Why Use Sanding Belts?

The many benefits of sanding belts in woodworking For starters, they provide a super smooth finish for painting or staining/varnishing. If you want your project to turn out looking great and professional, that smooth surface is paramount. Also, it can be used to remove the bad or damaged texture around the woods and hence sanding belts are best for ease of working. It provides safety that is why you would not have any cuts in your hands during work.

Sanding Belt- The biggest benefit of using sanding belt is, it can save a lot of time and effort. That being said, sanding by hand is a tedious and slow process no matter what; this becomes even more irritating if you have a big project that needs to be completed. A sanding belt allows you to easily remove material from the surface of the wood, which means that your time and energy are both conserved. That means more time using your woodworking plans and less time on labour.

Learning About Sanding Belts

By understanding how sanding belts work, you will be able to select appropriately the correct abrasive material for your project. The unique characteristics of every material make it well-suited or unsuited for specific jobs in woodworking.

A simple and common abrasive type is aluminum oxide, which works well for general-purpose sanding. Which means it may be applied on many forms of wood and composite supplies. The benefit use. Every. Net: silicon carbide is harder but more brittle. Great for those more dense hardwoods, oak and maple or whatever needs a little bit extra to get smooth. Zirconia alumina is one of the hardest, toughest materials used in wood; it can also be perfect for sanding abrasive surfaces like metal and other kinds.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID SR

SR ET

ET MT

MT TH

TH TR

TR FA

FA AF

AF MS

MS GA

GA CY

CY MK

MK EU

EU KA

KA LA

LA NE

NE